Connor-Winfield石英晶体的老化特性

Connor-Winfield石英晶体的老化特性,领先同行的康纳温菲尔德公司致力于帮助用户提供完美晶振解决方案,并通过自身的努力,研发设计各种创新型产品,其中最吸引人注意当属对于ConnorWinfield晶振产品的深入分析,同时也针对于产品的设计与分析提供对应攻略。

老化是晶体频率随时间的变化。必须在应用了解衰老的原因和方法用于测量它,可以实现一种预测速率的方法设备的使用寿命(10至20年)

老化的主要原因有两个,传质和应力。

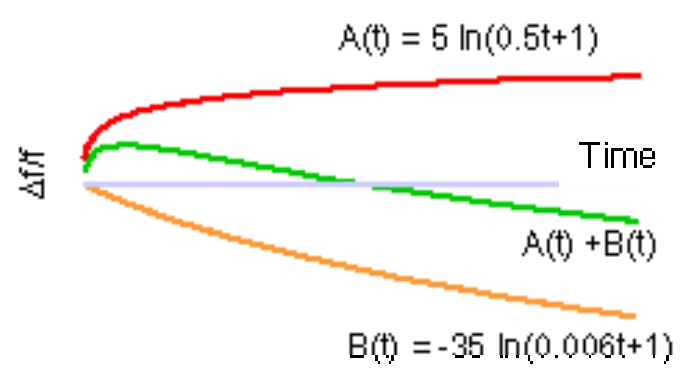

表1中:A(t)显示应力消除

B(t)显示污染效应

A(t)+B(t)就是组合。

如果设计受应力支配,则老化曲线将接近A(t)。同样,如果设计受到污染的影响老化将接近B(t)。

在现实世界中,这两种机制都存在。通过查看在上述曲线中,指出对数性质是很重要的曲线。水晶在生命早期以很快的速度老化,但是往往会随着时间的推移而稳定下来。

石英晶体随着质量的增加或去除而改变频率从晶片中取出。晶片上或中的材料未计数封装可以沉积或离开石英的表面,并且改变设备的频率。在实践中,晶体制造过程旨在保持所有材料尽可能干净可能的如果污染的质量等于石英被添加或从表面移除,然后频率将改变设备频率的每兆赫1ppm[2]。至关重要的是,结晶过程要尽可能干净实现良好的老化性能。

施加应力时,石英晶体会改变频率。这种压力可能来自几种来源中的任何一种或全部。包裹支架、环氧树脂连接、金属膜和石英本身可能是压力的来源。如果压力在的寿命内是恒定的部分,频率将保持不变。然而在现实世界中,压力会随着时间的推移而放松,因此会发生与压力相关的衰老。

封装材料(金属或陶瓷)具有与石英不同的膨胀系数。当石英被胶结时对于支架,它通常在高温下固化。当零件冷却时,热膨胀会使石英在压力下。适当的安装设计有助于减少这种情况。

导电环氧树脂或胶水用于与封装进行电气连接。固化过程中,环氧树脂收缩通过接头对石英施加应力。更柔软的环氧树脂并且可以使用硅来减少这种影响。然而环氧树脂(由于放气)是一个重要的潜力来源污染.Connor-Winfield石英晶体的老化特性.

石英中的应力可能来自棒或切割、研磨和抛光成晶圆的机械加工过程。

合成石英是在高压釜中从种子材料中生长出来的。种子的质量和一致性生长周期中的温度和压力影响棒材中缺陷的数量。这些缺陷,无论晶格结构中的污染物或位错可以是压力点。

石英是一种脆性材料。切割、研磨和研磨过程导致小的表面裂纹来自过程中使用的磨料颗粒。这些小裂缝在石英中产生应力。使用化学品的工艺蚀刻可以大大减少或消除表面[3]。

为了提高老化性能,或确保符合规范,准确的测量是关键。有几种方法可以可以使用,每个都允许在时间、成本和准确性方面进行权衡。设备的真正老化只能通过将其放置在电路和频率。这是不切实际的。因此,一种模拟10年或20年生命的方法是必要的以确保老化性能。在升高的温度下加速老化温度是为了实现这一点而发展起来的.

通过将温度提高到正常工作温度以上温度,可以加速晶体的老化。军事的规范[4]使用85°C 30天,使用105°C168小时,相当于25°C下的一年。其他行业标准使用85°C进行1000小时的第一年老化。测试的准确性越好,时间越长,越低温度情景[6]。Connor Winfield使用85°C1000小时作为其鉴定标准。

既然我们已经确定了时间和温度下一个问题是如何收集数据。有两种方法当前使用的。

第一种方法是被动老化。零件已序列化,并且之前在测量系统中的室温下测量以及烘烤之后。这是成本最低的选项,但它牺牲了准确性。被动年龄可以屏蔽传单并充当过程控制,提醒制造商注意问题.

第二种方法是主动老化。这是由执行的将每个晶振单元放置在振荡器电路中,以便在零件处于烘烤炉。一天可以进行多次测量从而可以为每个单元制作数据曲线。此曲线可以在数学上进行拟合,然后随着时间的推移进行投影允许长期预测[7]。主动老化方法导致更好的精度,但成本更高。

主动衰老的另一个好处是驱动结晶在测试过程中主动振动晶体更真实适应现实世界的条件。被动老化不会驱动晶体。

原厂编码

厂家

型号

T系列

频率

频率稳定度

CS-018-114.285M

康纳温菲尔德晶振

CS-018

MHz Crystal

114.285MHz

±100ppm

CS-023-114.285M

康纳温菲尔德晶振

CS-023

MHz Crystal

114.285MHz

±20ppm

XL-1C-010.0M

康纳温菲尔德晶振

XL-1C

MHz Crystal

10MHz

±50ppm

XL-1C-012.0M

康纳温菲尔德晶振

XL-1C

MHz Crystal

12MHz

±50ppm

XL-1C-020.0M

康纳温菲尔德晶振

XL-1C

MHz Crystal

20MHz

±50ppm

XL-1C-016.0M

康纳温菲尔德晶振

XL-1C

MHz Crystal

16MHz

±50ppm

XM-1-012.0M

康纳温菲尔德晶振

XM-1

MHz Crystal

12MHz

±50ppm

XM-1-016.0M

康纳温菲尔德晶振

XM-1

MHz Crystal

16MHz

±50ppm

XM-1-010.0M

康纳温菲尔德晶振

XM-1

MHz Crystal

10MHz

±50ppm

CS-034-040.0M

康纳温菲尔德晶振

CS-034

MHz Crystal

40MHz

±50ppm

CS-043-048.0M

康纳温菲尔德晶振

CS-043

MHz Crystal

48MHz

±25ppm

CS-044-054.0M

康纳温菲尔德晶振

CS-044

MHz Crystal

54MHz

±25ppm

XL-1C-018.432M

康纳温菲尔德晶振

XL-1C

MHz Crystal

18.432MHz

±50ppm

XM-1-018.432M

康纳温菲尔德晶振

XM-1

MHz Crystal

18.432MHz

±50ppm

CS-018-114.285MHZ

康纳温菲尔德晶振

CS-018

MHz Crystal

114.285MHz

±100ppm

Aging is the change in crystal frequency over time. This frequency change over the life of the part has to be accounted for in the application. Understanding the causes of aging, and the methods used to measure it, enables a method of predicting the rate over the life (10 to 20 years) of the device.

There are two main causes for aging, mass transfer and stress.

In table 1: A(t) shows stress relief

B(t) shows contamination effects

A(t) +B(t) is the combination.

If a design is dominated by stress, the aging curve will approach A(t). Likewise, if the design is dominated by contamination, the aging will approach B(t).

In the real world both mechanisms are present. By looking at the above curves, it is important to point out the logarithmic nature of the curves. Crystals age at a fast rate early in their lives, but tend to settle down with time.

Quartz crystals will change frequency when stress is applied. This stress can come from any or all of several sources. Package and mounts, epoxy connection, metal films, and the quartz itself can be sources of stress. If the stress is constant over the life of the part, frequency will stay constant. However, in the real world, stresses relax with time hence, stress related aging occurs.

Package materials (metal or ceramic) have different coefficients of expansion than quartz. When quartz is cemented to the mounts, it is usually cured at an elevated temperature. When the part is cooled, thermal expansion puts the quartz under stress. Proper mount design can help reduce this.

Conductive epoxy or glue is used to make electrical connection to the package. During cure, the epoxy shrinks and puts stress on the quartz through the joint. Softer epoxies and silicon can be used to reduce this effect. However, the epoxy (due to outgassing) is a significant source of potential contamination.

Stress in quartz can come from the growing process of the bars or the machining process of cutting, lapping, and polishing into wafers.

Synthetic quartz is grown in an autoclave from seed material. The quality of the seeds, and the consistency of temperature and pressure during the growing cycle impact the number of defects in the bar. These defects, whether contaminates or dislocations in the lattice structure, can be points of stress.

Quartz is a brittle material. The cutting, grinding, and lapping processes results in small surface cracks coming from the abrasive particles used in the process. These small cracks produce stress in the quartz. Processes using chemical etching can greatly reduce or eliminate this stress in the surface [3].

To improve aging performance, or to insure spec compliance, accurate measurements are key. There are several methods that can be used, each allowing for trade offs of time, cost, and accuracy. The true aging of a device can only be measured by placing it in circuit and frequency over the life of the product. This is unpractical. So a method to simulate 10 or 20 years of life is necessary to insure aging performance. Accelerated aging at an elevated temperature was developed to accomplish this.

By increasing the temperature above the normal operating temperature, aging in crystals can be accelerated. Military specifications [4] have used 85°C for 30 days and 105°C for 168 hours as an equivalent of one year at 25°C. Other industry standards use 85°C for 1000 hours for first year aging. The accuracy of the test is better for the longer time, lower temperature scenario [6]. Connor-Winfield uses 85°C for 1000 hrs as its standard for qualification.

Now that we have established the time and temperature, the next question is how to collect the data. Two methods are currently used.

The first method is passive aging. Parts are serialized and measured at room temp in the measurement system before and after the bake. This is the lowest cost option but it sacrifices accuracy. Passive age can screen fliers and act as a process control, which alerts the manufacturer to problems

The second method is active aging. This is performed by placing each crystal unit in an oscillator circuit so that frequency measurements can be made while the part is in the bake oven. Measurements can be made several times a day so that a data curve can be made for each unit. This curve can be mathematically fit and then projected out over time allowing for a long-term prediction [7]. Active aging methods result in better accuracy but at a higher cost.

Another benefit of active aging is the effects of driving the crystal. Actively vibrating the crystal during the test is truer to real world conditions. Passive aging does not drive the crystal during the test.

—

—

微信公众号

微信公众号